MULTI SPINDLE DRILL HEADS

HOLES: ANY SIZE, ANY QUANTITY, ANY PATTERN

BUCKEYE Fixed Center Multi Spindle Heads are designed to meet SPECIFIC requirements. Careful consideration is given to the machine being utilized. Clearances, input speeds, horsepower, and the mounting characteristics of your equipment are evaluated by our Engineering Department.

Spindle location, size of tools, and material specifications of the work piece are considered prior to laying out the gear train. Standard spindle designs are incorporated whenever possible to ensure rigidity and maintenance free service.

Layout is forwarded to the customer for approval prior to detailing, and a complete set of assembly and detail drawings (including parts lists) is made available.

Cover plates and gear boxes are carefully checked for hole spacing and bore sizes prior to assembly. Main assembly, spindles are checked for run out and parallelism. Spindle run out is held to .02 mm - non accumulative. Closer tolerances are held on "Precision" heads upon customer request.

LUBRICATION:

The following means of lubrication are available.

- Grease Pack

- Oil Circulating

- Oil Splash

- Oil Mist

INSPECTION PROCEDURE AND TOLERANCES:

Cover plates and gear boxes are carefully checked for holes spacing and bore size prior to assembly. After assembly, spindles are checked for run out and parallelism is held to .0.2 mm Spindle spacing is held to +/-.02 mm – non accumulative.

Closer tolerances are held on “precision’ heads upon customer request.

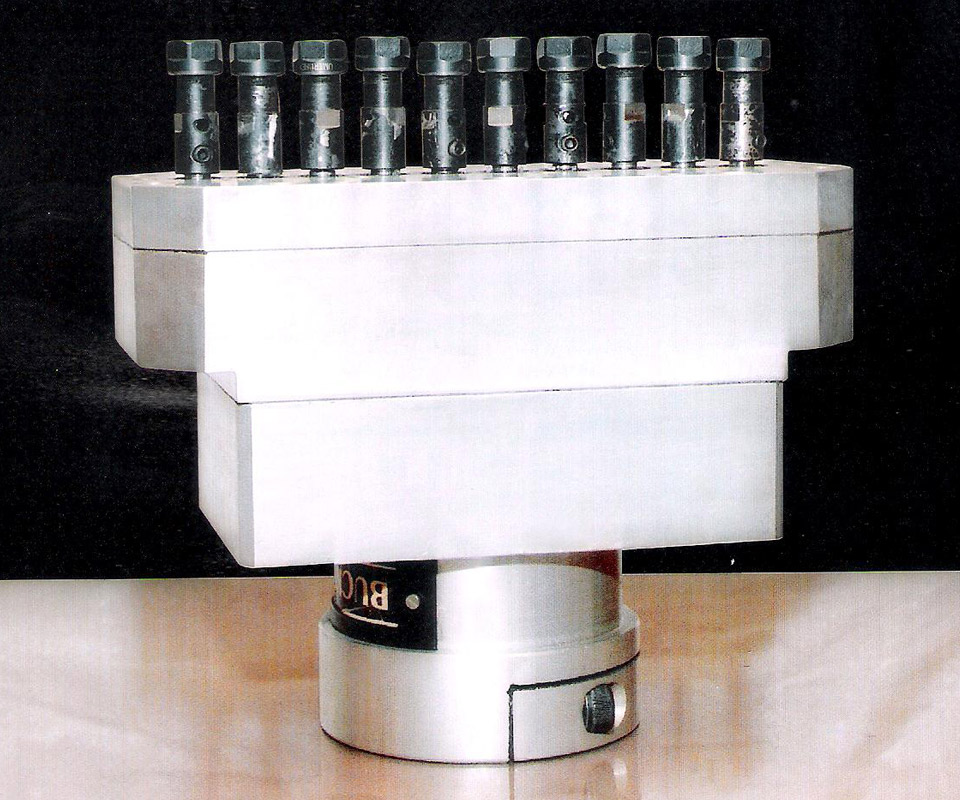

# 1. Eight Spindle Heavy Duty Drill Head.

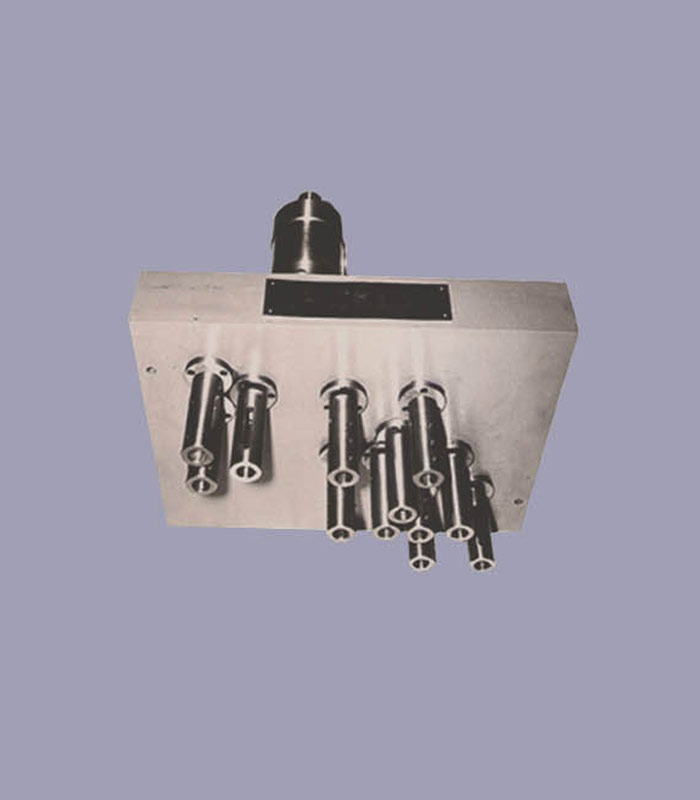

# 2. Ten Spindle Close Center Drill Head.

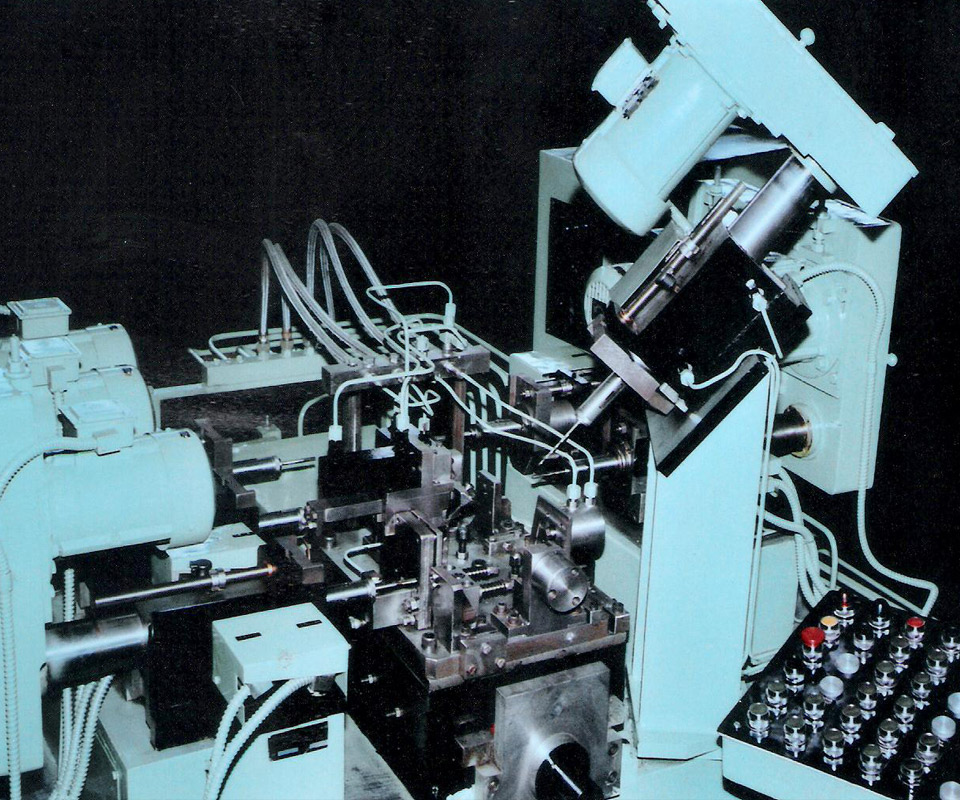

# 3. Custom Designed Multi spindle Drilling & reaming Machine. For Sewing Machine Base Plate.

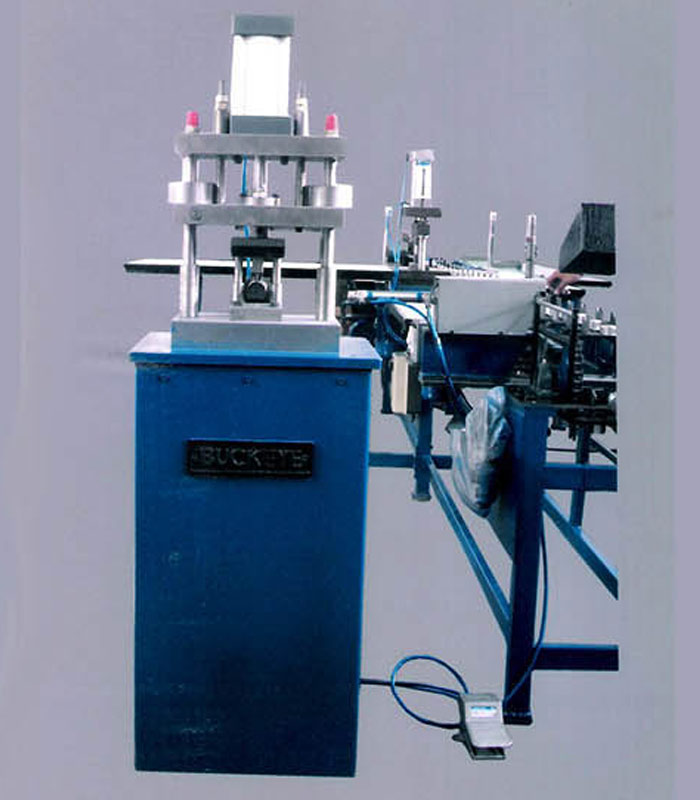

MULTI SPINDLE DRILLING MACHINES

BUCKEYE offers multi-spindle drilling and tapping machines designed and built to your exact requirements. These machines can be customized to drill and tap holes in any quantity, size or pattern. Carefully engineered and precisely manufactured. BUCKEYE multi-spindle drilling and tapping machines will deliver the ultimate in high production, versatility and productivity.

The BUCKEYE Multi-Spindle Drilling Machines perform a variety of drilling, tapping and deep holes drilling ... plus counter boring, spot facing and chamfering operations. They are rugged, packed with power, precision engineered and are the most productive multi spindle drilling machines you can buy and price is right-by design. Price is below any comparable, automatic cycle multi-spindle machine with hydraulic table feed or CNC Controlled Cycle.

All of this means savings added to savings. A BUCKEYE machine is designed to meet the customer's cost per part, part per hour, quality of product and predicted payout requirements year after year. The machine pays for itself. And then it starts to pay for itself all over again.

Custom designed CNC production machines High productivity at Low Investment.

View all!

Feel Free to Call Us

+91 9627290555

Mail Us Now

info@buckeyemachines.in

Office Address

Post Box # 64, D46-48, Industrial Estate

Aligarh, U.P., PIN - 202001, India